Fluid pumps allow homeowners and professionals to remove fluid from an area and transport it to a desired location. Centrifugal and submersible pumps are two of the most common pump types, working to move water efficiently.

While they both move fluids, they work slightly differently and perform better in different situations. Finding the right pump for your needs is essential to ensure your site’s safety and efficiency.

What Are Submersible Pumps?

Submersible pumps sit under the water or fluid they pump. Submersible pumps use a pump unit and motor to move water out of the area, typically to help with drainage. With their underwater design, these pumps are an efficient, quiet, low-maintenance solution for your drainage needs.

Submersible pumps work by creating kinetic energy from electrical energy to move fluid away from the pump opening. Every submersible pump has a motor that moves an impeller. Impellers rotate, creating centrifugal force, drawing fluid into the pump and through a filter. As the impeller spins, it uses pressure and velocity to send fluid through pipes and away from the initial area. They can be centrifugal pumps or turbine pumps, as long as they sit under the water.

Submersible Pump Uses

You’ll see submersible pumps for any space that needs regular draining and fluid redirection. They’re popular choices for:

- Irrigation systems

- Well water extraction

- Drainage

- Sewage pumping

What Are Centrifugal Pumps?

Centrifugal pumps sit above the water. Like submersible pumps, they use centrifugal force to operate. Centrifugal pumps are much easier to access since they’re positioned above water and can transport many fluid types thanks to the force they generate.

In centrifugal pumps, fluid enters the pump, and an impeller begins to rotate. This rotation increases the fluid’s velocity, turning it into high-pressure fluid. Then, it gets sent through a diffuser, and it flows to its next destination. Using centrifugal force allows pumps to be produced at relatively low costs.

Centrifugal Pump Uses

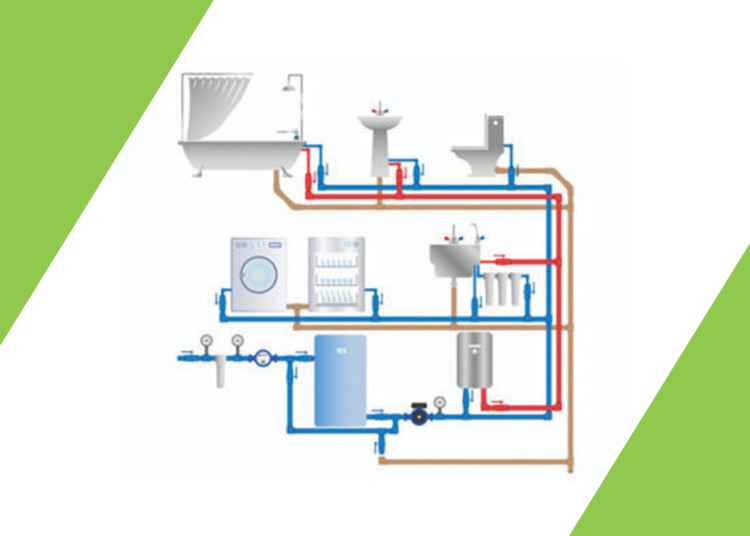

Centrifugal pumps are popular in many industries and are often used for domestic, agricultural, and industrial uses. Some centrifugal pump applications include:

- Chemical processing

- Water supply

- Heating, ventilation, and air conditioning (HVAC) systems

What’s the Difference Between Submersible and Centrifugal Pumps?

Submersible and centrifugal pumps are efficient, reliable pumps when used in the right circumstances. Understanding their differences helps you get the best pump for the job, improving efficiency and protecting your site. Here’s a breakdown of the differences between centrifugal and submersible pumps to ensure you get a pump that fits your needs:

1. Design

Submersible pumps have a pump unit and motor that sit inside waterproof housing to avoid electrical problems. As submersible pumps sit underneath the water, they operate quietly and efficiently.

Centrifugal pumps also have an impeller inside the casing, but the casing is not entirely waterproof. They usually have an external motor encased in a protective housing that sits separate from the impeller.

2. Location

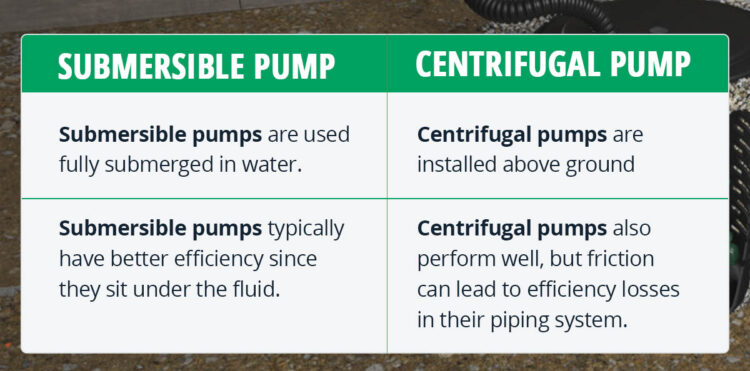

Submersible pumps are used fully submerged in water. They sit completely underneath the water they pump, operating continuously to drain fluid. They’re best for locations where you want to hide the pump or have limited dry space. In comparison, centrifugal pumps are installed above ground, not underwater. They always sit outside of the fluid that needs pumping.

3. Use

Submersible pumps must be submerged to work, so they operate best when used in deep water. Drainage, sewage pumping for homes and buildings, and well water extraction are all great uses of submersible pumps.

Centrifugal pumps need enough space to be installed in shallow water or near the draining area. They’re ideal for pumping low-viscosity liquids and many different materials, such as chemicals, organic liquids, solvents, and more.

4. Efficiency

Since submersible pumps sit under the fluid, they typically have better efficiency — sitting above the water increases friction and fluid turbulence. As a result, submersible pumps are excellent for high-flow applications. Centrifugal pumps also perform well, but friction can lead to efficiency losses in their piping system.

5. Maintenance

Submersible, non-centrifugal pumps experience less elemental exposure and need less maintenance than centrifugal pumps. However, their location makes maintaining slightly more complex. Centrifugal pumps need more maintenance, but they’re fairly straightforward to service.

For submersible pumps, maintenance typically involves:

- Checking and cleaning components like the motor housing, impeller, and pump intake.

- Cleaning and replacing filters.

- Inspecting bearings, seals, and cables — replace these components if they’re worn during inspections.

- Monitoring water levels to prevent dry running and protect your pump.

In comparison, maintaining a centrifugal pump may include:

- Cleaning debris from the intake.

- Inspecting the casing, impeller, and seals for wear.

- Ensuring proper pump motor alignment.

- Lubricating bearings.

- Looking for shaft seal leaks.

- Testing and calibrating flow and pressure sensors.

6. Cost

Submersible pumps are usually more expensive to install, but their easy maintenance and good efficiency make them more cost-effective in the long term. Lower maintenance costs can significantly impact your budget, letting you invest your money elsewhere.

When buying centrifugal pumps, remember to consider the initial and long-term operating costs to help you avoid excessive spending. Their more affordable upfront cost makes them appealing, although you will pay more for maintenance in the long run.

Overall, aim to get the pump that fits your budget and job needs.

How to Choose the Right Pump

When choosing between submersible and centrifugal pumps, consider the job, site, cost, and your needs. The right pump will efficiently transport fluids from your site, letting you safely complete your work. You need a pump that can fit the area and pump fluid at the rate you need without losing too much efficiency.

Consider centrifugal, non-submersible pumps when:

- You need a pump that is easy to install and maintain above the ground.

- You’re dealing with shallow water sources like tanks, ponds and rivers.

- You want something more cost-effective for your moderate to low-head applications.

You should look at submersible, centrifugal pumps when:

- You need a pump that can handle higher flow rates and pressures.

- You want something with longer durability and life, especially in harsher environments.

- You’re looking for a quieter pump with a lower risk of priming issues.

- You need a pump for deep water sources like a deep private well.

Talk to an expert pump supplier if you need help choosing between submersible and centrifugal pumps. These professionals have the experience to help you get the best model for the job, saving you money and time.

Get High-Quality Pumps From Zoeller Pump Company

If you’re looking for dependable submersible and centrifugal pumps, explore our extensive stock today. As a leader in the wastewater industry, Zoeller Pump Company is your go-to source for high-quality pumps and unmatched customer service. Our over 70 years of industry experience allow us to provide innovative pump solutions and exceed your expectations. All of our products are made in the USA with 95% domestic materials.

Find a Zoeller Pump dealer near you and enjoy quality pump solutions for your home, business or project site.