Ensuring a consistent supply of clean and safe drinking water is essential for the health and well-being of any community. Municipal water treatment plants help achieve this goal by using sophisticated processes to convert raw water into potable water. These processes rely heavily on the efficient and dependable movement of water between various treatment stages, making pumping solutions an absolutely critical component. Zoeller Pump Company, a well-established manufacturer with a long-standing reputation for quality and durability, offers a comprehensive range of pumps that are ideally suited for the rigorous demands of municipal water treatment projects.

The Crucial Role of Pumps in Water Treatment

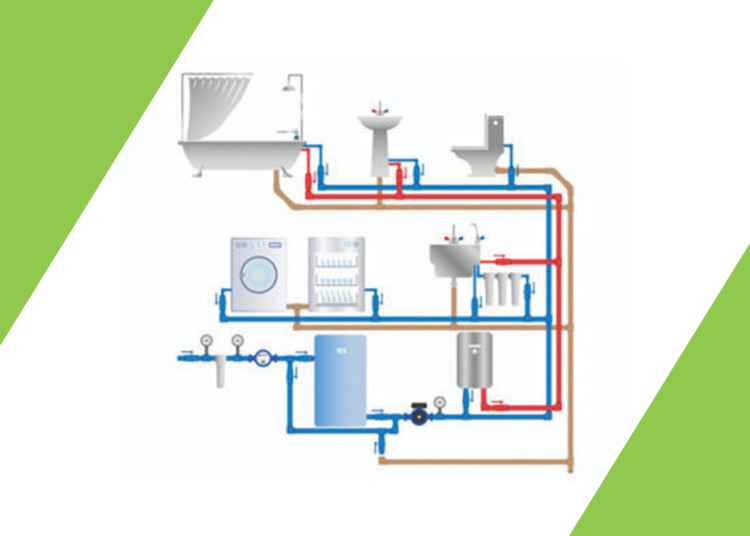

Pumps play a fundamental role in water treatment. Water treatment involves a series of processes designed to remove contaminants and make water safe for consumption. Pumps are important in almost every stage of this process, facilitating the movement of water between different treatment units. In the initial stage, raw water intake pumps draw water from the source, whether it be a river, lake, or groundwater well, and deliver it to the treatment plant.

Within the treatment plant, various types of pumps transfer water between different treatment stages. They can move the water through coagulation and flocculation basins, sedimentation tanks, filtration units, and disinfection systems. These transfer pumps need to be reliable to ensure a continuous flow and prevent disruptions in the treatment process.

Treated water distribution pumps are crucial for delivering the purified water to the distribution network, ensuring adequate pressure and flow to reach consumers. These pumps often operate continuously and must be highly efficient to minimize energy consumption and operational costs. Choosing the right pump for each stage of the water treatment process is critical. Municipalities can consider factors such as flow rate requirements, the nature of the fluid being pumped, and energy efficiency.

Types of Pumps for Municipal Water Treatment

Zoeller Pump Company offers a wide array of pump types designed to meet the diverse demands of municipal water treatment projects. Their reputation for quality, durability, and reliable performance makes them a preferred choice for engineers and operators in this sector. Some of the key pump types utilized in municipal water treatment include:

Effluent Vertical Turbine Pumps

In municipal water treatment, these pumps are ideal for moving effluent from sedimentation basins or clarifiers to subsequent treatment stages like filtration or disinfection. Their vertical design saves space, and their durable construction ensures reliable operation in demanding environments. Zoeller Pump Company’s effluent vertical turbine pumps contribute to efficient and continuous wastewater processing within the treatment plant, facilitating the production of high-quality treated water.

Centrifugal Pumps

The centrifugal pump is a versatile pump that utilizes a rotating impeller to transfer kinetic energy to the fluid, enhancing its pressure and flow rate. Centrifugal pumps are widely used for various transfer applications within the treatment plant, including moving water between treatment basins and for boosting pressure in distribution systems. Zoeller Pump Company offers a range of centrifugal pumps with different construction materials and impeller designs to suit specific fluid handling requirements. They are suitable for large-scale pump applications.

Submersible Pumps

These pumps are designed to be submerged directly in the fluid they are pumping. They are particularly well-suited for raw water intake from wells or sumps, as well as for handling wastewater and sludge within the treatment plant. Zoeller Pump Company’s submersible pumps are known for their sturdy construction, corrosion-resistant materials, and ability to handle solids.

They are ideal for demanding applications such as handling sewage and slurry, often used in sump applications and sewage treatment facilities. The main difference between submersible and centrifugal pumps is that the latter is installed above ground, while the former is fully submerged in water.

Grinder Pumps

Grinder pumps are essential in situations where wastewater or sludge containing solids needs to be moved. These pumps feature a grinding mechanism that macerates solids into a slurry, allowing it to be pumped through smaller diameter pipes and preventing clogging.

Zoeller Pump Company’s grinder pumps are known for their powerful grinding capabilities and reliable performance in handling challenging wastewater streams within the treatment process. They can be retrofitted to existing positive displacement pump installations, which can handle high-viscosity fluids and are sometimes used in specific wastewater treatment applications.

Non-Clog Pumps

Similar to grinder pumps but designed for larger solids, non-clog pumps are crucial for handling raw sewage and sludge in wastewater treatment components of a municipal system. Zoeller Pump Company offers a range of non-clog pumps with impeller designs that allow for the passage of solids without causing blockages, ensuring continuous and efficient operation.

Case Study

Zoeller Pump Company has a proven track record of providing effective solutions for municipal wastewater challenges. In South Central Wisconsin, a failing aerobic package plant caused public concern due to excessive maintenance and subpar wastewater discharge. Zoeller Pump Company collaborated with a local engineering firm to design and implement a recirculating media filter system (RMF) capable of managing 14,000 gallons per day. This solution resolved the immediate wastewater issues and established an environmentally responsible system, easing community concerns.

Municipalities facing similar issues with aging infrastructure or looking to improve effluent quality can adopt RMF systems to enhance their wastewater treatment processes. Zoeller Pump Company’s RMF systems provide a reliable and environmentally sound solution for achieving cleaner water discharge, reducing maintenance, and promoting community well-being. The modular design of RMF systems also allows for scalability, making them suitable for various community sizes and wastewater treatment needs.

Impact on Community Water Management

Using reliable pumps, such as those provided by Zoeller Pump Company, has a significant positive impact on the communities served by municipal water treatment plants in these ways:

- Consistent water quality: Reliable pumps ensure a steady water flow through the treatment process. This reliability lets each stage function optimally and consistently remove contaminants. It directly translates to the community receiving a higher quality of treated water.

- Public health protection: By facilitating the effective removal of harmful pathogens and contaminants, reliable pumping systems are essential for safeguarding public health and preventing waterborne diseases.

- Operational efficiency: Energy-efficient pumps and durable designs contribute to lower operational costs for the municipality. Reduced energy consumption and less frequent maintenance translate into significant long-term savings.

- Sustainable water management: By ensuring the efficient use of energy and minimizing disruptions in the treatment process, reliable pumping systems support more sustainable water management practices.

- Efficient water distribution: A well-functioning water treatment system, powered by dependable pumps, helps ensure efficient water delivery to communities, meeting the needs of residents and businesses.

Partner With Zoeller Pump Company for Quality Municipal Water Treatment Pumps

At Zoeller Pump Company, we offer a valuable portfolio of pumping solutions made in the USA using 95% U.S. content. Our pumps are ideal for meeting the demanding needs of municipal water treatment projects. By choosing us, municipalities can ensure the consistent delivery of clean water and protect public health. Call us today at 800-928-7867 for more information about our pumps or find a distributor near you to buy the pumps you need for your community water systems.