Water pumps are the unsung heroes of homes and jobsites. These systems prevent flooding and remove sewage to keep things clean and dry. Caring for water pumps is vital for long-lasting performance. Maximizing durability saves money, reduces downtime, and prevents unexpected failures. It ensures reliable performance for residential and commercial applications.

This guide explores how to get the most from a water pump — from choosing the right pump to maintenance tips. Ready to keep your systems running strong for years to come? Let’s dig in and make pump problems a thing of the past.

Factors That Affect Pump Lifespan

Usage, water quality, installation — all these and more contribute to a pump’s lifespan. The following affect longevity:

- Material quality: Construction impacts pump durability. For example, cast iron components will last longer than plastic.

- Water quality: Abrasive particles, chemicals, or high acidity can speed up wear and corrosion.

- Lack of maintenance: Failing to maintain your pump can affect its service life.

- Operating conditions: The pump’s environment and usage affect its longevity. High frequency, pressure, temperature, or dry-running can shorten a pump’s lifespan.

- Poor installation: Misalignment, incorrect piping, or inadequate support can lead to premature failure.

- Cavitation: When the pressure inside the pump drops too low, it causes vapor bubbles to form and collapse. This cavitation can damage the impeller and pump housing.

- Pump type: Using a pump outside its intended operating range can reduce its lifespan.

- Corrosion: Chemical reactions between the pump materials and the water can lead to rust and deterioration. Sand, silt, and other particles in the water can grind away at the impeller or internal components.

9 Ways to Maximize the Durability of Pumps

A water pump is a significant investment that can last 10 years or more, depending on the type and application. With proper care, pumps can last even longer. For example, a contracting team uncovered a 47-year-old Zoeller sump pump at a home in Newington, Connecticut.

While 47 years is rare for most pumps, these strategies can help increase water pump lifespan:

1. Choose the Right Pump for the Job

The first rule of pump longevity is selecting a pump appropriate for the application. A mismatched pump may experience strain, leading to overheating and early wear. Different fluids need specific pump materials to prevent corrosion and clogs. Know your pump’s limitations! Consult a professional to ensure you select the right pump for your application.

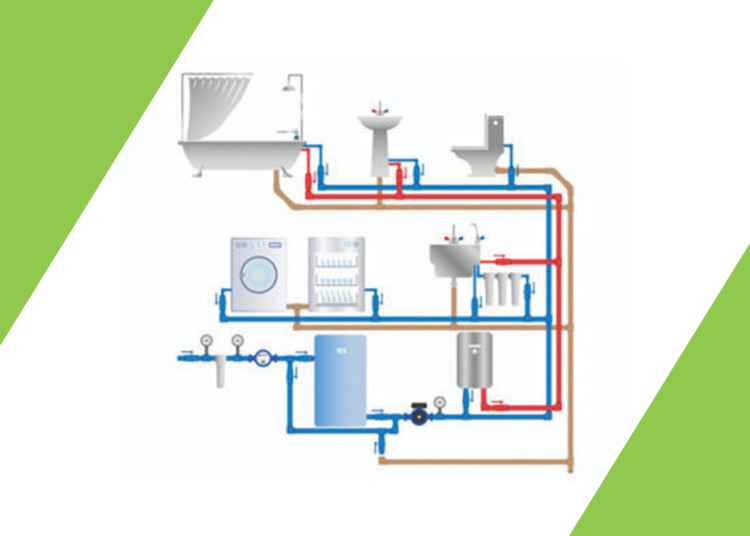

2. Ensure Proper Pump Installation

Together with investing in a high-quality pump, proper installation is key to durability. Installation flaws can strain the pump’s components, leading to premature wear or failure. They may also cause cavitation or overheating. Correct wiring, piping, and support ensure the pump operates as intended.

Follow the manufacturer’s guidelines and best practices during installation to maximize the pump’s efficiency, reliability, and longevity.

3. Take a Proactive Maintenance Approach

Regular maintenance is a pillar of boosting water pump durability. It stops minor issues from escalating into major failures, saving on repairs and downtime. Maintenance tasks include inspection, lubrication, and cleaning. These health checks protect the pump’s critical components.

The three types of pump maintenance include:

- Reactive maintenance: This type of maintenance happens once a pump fails. While the upfront costs might be lower, the repair and downtime costs are higher.

- Preventive maintenance: You can prevent major repairs by planning maintenance at regular intervals. Create a maintenance schedule to keep track of important tasks. Preventive maintenance is the sweet spot. It reduces failure risk, enhances pump efficiency, and boosts its service life. Scheduled servicing involves recurring costs, but saves money in the long run.

- Predictive maintenance: Anticipating issues can save significant cost and downtime. Predictive maintenance relies on technology. It uses data and sensors to monitor the pump’s condition, warning you of potential problems. The long-term savings offset the more expensive set up cost.

4. Replace Worn Seals

Seals are a crucial component of water pumps. They create a barrier that stops fluid from leaking out and contaminants from getting in. Over time, seals wear or deteriorate. Replacing damaged seals improves performance, maintains pressure, and extends lifespan.

5. Monitor Key Health Indicators

Pay attention to the following critical elements to extend your pump’s life:

- Shaft wear: Over time, the shaft can wear down, causing bearing issues and damage. Operating the pump outside its optimal range can also stress components and bend the shaft. Monitoring and addressing these factors ensure reliable operation and prevent costly repairs.

- Vibrations: Excessive vibration can signal a bent shaft or misalignment. These issues may damage critical components and shorten the pump’s life.

- Lubrication: Proper lubrication is crucial for water pump health. Under-lubrication can lead to bearing seizure, while over-lubrication can cause overheating and leaks. Monitoring lubrication levels prevents premature failures.

6. Pay Attention to Alignment

Misalignment is a leading cause of inefficiencies and failures. A misaligned shaft uses more energy, increasing power consumption while reducing efficiency. Misalignment also causes excessive vibration. Swift realignment relieves stress and wear on critical components, improving durability.

7. Operate at the Best Efficiency Point

Part of maximizing pump durability is understanding the following performance indicators:

- Pump curve: This chart shows how the pump performs in relation to pressure head and flow.

- Best efficiency point (BEP): A pump’s BEP is the point along its curve where it operates at peak efficiency. The BEP is the ideal balance of pressure (head), energy consumption, and flow rate.

Operating the pump within the recommended BEP optimizes performance. A degree of deviation is acceptable, but straying too far outside this range impacts durability. Stick as close to the BEP as possible to ensure long-term reliability and efficiency.

8. Avoid Running the Pump Dry

Unless designed for dry use, water pumps need fluid to function. Dry running a pump can damage its internal components through overheating or cavitation. Without lubrication, the shaft and bearings generate excessive heat. This friction causes accelerated wear and potential melting of plastic components. Mechanical seals may deteriorate due to rapid temperature changes.

To protect your investment, understand the pump’s limitations. Avoid dry running unless the pump type allows it. Speak to a trusted pump manufacturer or distributor if you need a dry-run model.

9. Get Smart About Technology

Smart technology and remote monitoring are powerful tools for extending longevity. A smart pump uses digital sensors and Internet of Things (IoT) features to collect performance data. This real-time data allows for early threat detection. Diagnosing and resolving these threats prolong the service life of components. Remote monitoring enables proactive maintenance based on actual pump conditions rather than schedules.

For example, pumps with variable frequency drives (VFDs) adjust flow according to demand. This ability reduces waste and wear on the pump’s components.

Maximize Durability With Zoeller Pump Company

A long-lasting water pump starts with a quality product. Zoeller Pump Company is a trusted water pump manufacturer committed to high-quality solutions. Made in the USA using 95% U.S. content, we design our pumps to last. We focus on customer value. That’s why our team provides genuine support throughout the entire sales process. With Zoeller Pump, you enjoy long-term satisfaction and reliability.

Ready to maximize your pump’s durability? Find your nearest Zoeller Pump distributor and get the best pump for your needs.