When you think of water damage, elevators probably aren’t the first area that comes to mind. After all, they’re usually suspended well above the ground. At the base of the elevator shaft, however, is what’s called an elevator pit. The pit houses many electrical components that the elevator needs to work. If water leaks through the shaft and floods this area, it can damage these components and cause the elevator to malfunction.

This is where elevator sump pumps come in. A lesser-known building safety solution, these mechanisms are designed to drain water from places like basements and elevator pits and send it into the sewage system. In doing so, they prevent flooding and keep the elevator running smoothly. In this article, we’ll talk about just how important these sump pumps are and how you can go about installing and maintaining one.

Why Use an Elevator Sump Pump?

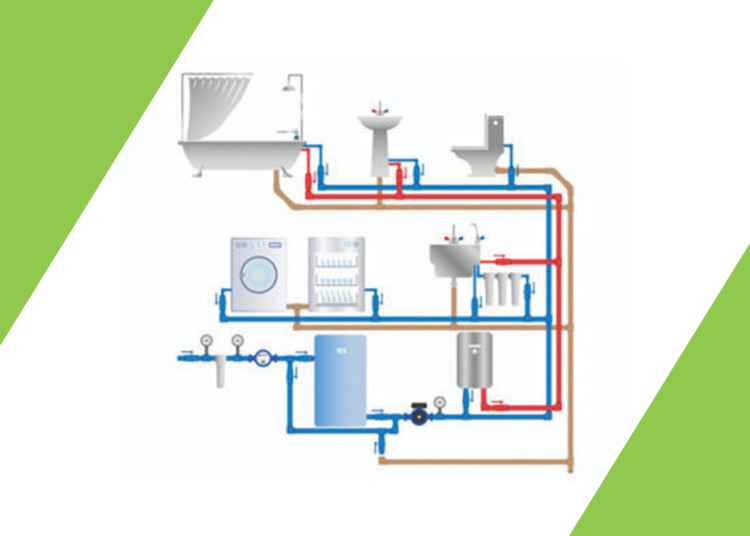

As outlined above, water can leak into elevator pits and pool there. This often happens as a result of flooding, plumbing malfunctions, or nearby groundwater leaking into the pit — either through the building itself or through the earth outside the walls of the shaft. The sump pump’s job is to remove this water from the pit to prevent damage. Removing the water also makes it easier to find the cause of any leaks and resolve them.

If there’s no pump in place, the water can:

- Short-circuit the electrical components in the pit.

- Become a breeding ground for pests and mold.

- Rust the base of the shaft and even weaken the building’s foundations.

As a result, you may have to shut the elevator down for drainage and repairs, which is a huge inconvenience for you and anyone who would normally use the elevator. Even the most expensive buildings in the world aren’t immune to these challenges.

This is why flood prevention measures like sump pumps are so important. They keep the ecosystem of your building flowing, saving you time and money, protecting everyone’s convenience, and preventing accidents.

Sump Pump Types and Parts

There are two main types of elevator sump pumps to choose from:

- Submersible pumps: These pumps are quite popular and are often used in home basements that regularly deal with groundwater and flooding. They sit directly in the water and pump it from there.

- Pedestal pumps: As the name implies, these pumps sit above the elevator pit and pump water out of it through a hose. This elevation makes them easier to access and repair if there’s a malfunction. It also makes the pumps louder on average since there’s no water to muffle the noise they produce.

While there are some key differences between the two in terms of design, these pump types have many parts in common, including:

- The elevator sump pit: This pit within a pit is where the water and other debris from the elevator shaft pools so that it can be pumped out easily and efficiently.

- The pump unit: This mechanism powers the entire system, pumping the water out of the pit and into the sewage system.

- The float switch: This contraption floats on the surface of the water and activates the pump once that water reaches a certain height. It’s essentially an on/off switch controlled by the water itself. Elevator systems use our Oil Smart technology, which uses sensor probes in place of a float switch. This keeps the oil inside the elevator pit instead of being pumped out.

- The discharge pipe: All that water and waste needs somewhere to go, and the discharge pipe is what takes it there. It connects the pump directly to the array of pipes leading to the sewage system.

- The check valve: The pump has to move the water against gravity, which takes a lot of energy. Should the system fail, the check valve is in place at the mouth of the discharge pipe to keep all that water from flowing back down the pipe and into the pit.

- The alarm system: Some pumps come equipped with alarms that can warn you if there’s a pump malfunction or if the water rises too high. This mechanism protects the elevator pit and lets you know maintenance is needed. There is also a high oil alarm with our Oil Smart system.

Installation Process and Safety Regulations

The step-by-step installation process will vary based on the dimensions of the elevator pit and the type of sump pump chosen, but there are some commonalities across this process for all pumps. These include:

- Creating the sump pump pit at the base of the elevator shaft.

- Connecting the discharge pipe to the existing pipe system.

- Hooking the pump itself up to the electrical system.

- Testing the system once it’s installed.

The American Society of Mechanical Engineers (ASME) sets many of the guidelines for both the installation and use of these pumps, though it’s also important to adhere to guidelines, restrictions, and building codes imposed at the state and local levels.

One of the most important rules set by ASME is that elevators with Firefighters’ Emergency Operation must also have sump pumps in their elevator pits. You can read more about this rule in Section 2.2.2.5 of ASME A17.2-2020, ASME’s guide for elevators and similar transportation systems.

To keep up with these guidelines and to make sure your pump is installed properly, it may be best to turn to plumbing professionals who have the experience necessary to work with your system throughout its life.

Maintenance Tips

An elevator sump pump requires regular maintenance to keep pumping smoothly. Your maintenance procedure should include:

- Inspecting the check valve for debris.

- Visually checking the inside of the discharge pipe for blockages.

- Checking the pump’s various mechanisms for water damage and other wear.

- Inspecting the elevator pit and the walls of the shaft for cracks and water damage.

- Regularly testing the float switch, alarm system, and the pump as a whole to make sure they’re functioning properly.

If you identify cracks, blockages, or broken parts, don’t worry. Wear is a normal part of the sump pump’s lifespan. However, you should still try to resolve these issues as soon as possible. Otherwise, the pump may sustain further damage, which could exacerbate the issue and result in more costly repairs.

Invest in High-Quality Sump Pumps

Whether you’re looking for pumps for your property or for a client, Zoeller Pump Company has you covered. We offer a wide range of sump pumps that are perfect for elevators, and we’ve been creating and improving them in Louisville, Kentucky, since 1939. You’ll find that history in all of our pumps, each of which is made right here in the U.S. using 95% U.S. content.

To learn more, fill out our contact form or call us at 800-928-7867.