Sewage grinder pumps are important for moving wastewater to municipal sewer mains. Not all residential and commercial properties need sewage grinder pumps, but this type of pump is essential for homes and business buildings that are located under municipal sewer system levels. Most standard buildings are located above the sewer lines so gravity can pull wastewater down into the municipal system, but grinder pumps can move wastewater upwards for homes and businesses that cannot rely on gravity.

Sewage grinder pumps operate similarly to regular sewage pumps, but they grind solid waste before sending wastewater to the sewer system. They also operate with more power than typical sewage pumps because they use pressure to force wastewater upwards. Continue reading to learn about sewage grinder pumps, what type of properties need grinder pumps, and how to properly maintain grinder pumps.

What Are Sewage Pumps?

Sewage pumps move sewage and soiled water to a gravity flow sewer main, leach field, or septic tank. They are also known as sewage ejector pumps, and they can move waste horizontally using impellers that provide adequate pressure to do so. Many standard homes use them to move their wastewater to a municipal sewer system, which collects wastewater for water treatment facilities. Water treatment is important for human health and the environment.

What Are Sewage Grinder Pumps?

Sewage grinder pumps are sewage pumps that include cutter blades. Sewage grinder pumps work similarly to sewage pumps because they use impellers to move waste. However, unlike simple sewage pumps, they use cutter blades to grind or pulverize solid waste. The grinding feature allows solid waste to pass through narrow lines with smaller diameters. Grinder pumps also operate with more power than typical sewage pumps. They move wastewater in areas where gravity service is unavailable.

How Does a Sewage Grinder Pump Work?

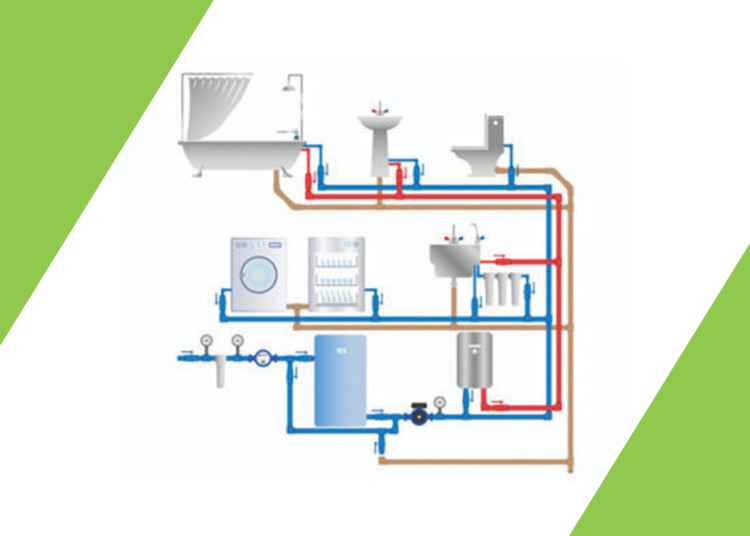

A sewage grinder pump grinds solid waste and pumps wastewater into the public sewer system. Grinder pumps function similarly to garbage disposals. They grind wastewater from showers, toilets, and washing machines and then pump it to the sewer system.

A grinder pump sits inside a buried outdoor tank that stores wastewater from a residential home or commercial building. A steel blade shreds solid waste to prevent blockage. When the tank’s wastewater reaches a certain level, the pump activates and uses a pressure discharge line to force the wastewater into the public sewer system.

Grinder pumps are electricity-powered. A sewage grinder pump uses a float switch or connects to a control panel wired to a circuit breaker. Grinder pumps contain the following components:

- Tank

- Pump

- Level controls

- Control panel

- Piping

- Valves

- Electrical components

Grinder pumps generate higher head pressure to force wastewater upwards or over longer distances to reach the sewer system. Because they grind solid waste into very fine particles, they can operate with smaller pipes to move wastewater.

Uses for Sewage Grinder Pumps

Regular sewage pumps move wastewater using gravity, but buildings and residences can use grinder pumps to force wastewater upwards when they are located lower than the gravity sewer main. Grinder pumps generate higher pressure to move wastewater for buildings that cannot rely on gravity to reach the sewer system.

A home or commercial building may also need a sewage grinder for a pressure sewer system. If a municipal sewer system is pressurized, all wastewater must also be pressurized to enter. Pressurized sewer mains will block unpressurized water from entering, so a pressurized pump is essential. Sewage grinder pumps use pressure to move waste upwards, and this same pressure is sufficient to push the water into a pressurized sewer system.

Why Are Sewage Grinder Pumps Important?

Standard homes are typically higher than municipal sewer lines so waste can easily move to the sewer system via gravity. However, homeowners and business owners located below the municipal sewer lines could experience wastewater backup if they use a regular sewage pump.

Sewage grinder pumps protect residential homes and commercial buildings from wastewater backup and dangerous contamination because they help wastewater reach treatment facilities where it can be treated and safely released into the environment.

When Should You Not Use a Sewage Grinder Pump?

A sewage grinder pump is only necessary when a commercial building or residence needs to pump wastewater horizontally, upwards, or a long distance to a sewer system. If a household or business owner uses a septic system, they should not use a grinder sump pump system.

Sewage grinder pumps are not compatible with septic systems because grinder pumps break waste into particles that are too small for a septic system to filter. Septic systems work by separating solids from liquid waste, and a grinder pump can prevent a septic system from doing so.

Types of Sewage Grinder Pumps

The type of sewage grinder pump you need depends on the type of building it will serve. Commercial buildings need a different type of grinder pump than residential homes due to the amount of wastewater they produce. The more bathrooms and kitchens a property has, the more wastewater it will produce, requiring more power and speed to move wastewater.

Residential Sewage Grinder Pumps

A residential grinder pump offers adequate performance for residential family homes. A residential grinder pump can handle the wastewater a family produces from their toilet, shower, and kitchen use.

Commercial Sewage Grinder Pumps

Commercial grinder pumps are ideal for large buildings that serve as office spaces, hotels, rental properties, restaurants, food processing companies, and bars. A commercial grinder pump has a more powerful motor than residential grinder pumps, so it can handle more wastewater.

It’s important for commercial buildings to use commercial grinder pumps, because residential grinder pumps could potentially become overwhelmed with excessive wastewater from a large building. Opting for a commercial grinder pump can help a business maintain the longevity of its pump and avoid costly repairs or replacements.

Important Considerations for Choosing a Sewage Grinder Pump

Choosing the right sewage grinder pump ensures it works efficiently, lasts longer, and sends water to the sewer system properly. Since different buildings produce varying amounts of wastewater, each one must have a grinder pump that can adequately handle its water output and push it to the sewer system.

A system with the right power, design, head height, speed, and flow rate will grind solid waste and move wastewater to the public sewer system without becoming clogged or backed up. The right grinder pump will also prevent potential damage, saving money on repairs and maintenance.

Revolutions Per Minute

A grinder pump’s revolutions per minute (rpm) determines how well it can grind solid materials. The faster a pump can shred materials into a slurry, the better it can prevent clogging and backups. A commercial business may need a higher rpm if it needs to grind more solid waste. For example, a brewery may need a grinder that can handle hops or grains in wastewater, and a hotel may need a grinder that can handle unexpected waste items that guests flush down the toilet.

Horsepower

The horsepower a grinder pump requires to operate efficiently and reliably depends on the amount of wastewater a building produces. A grinder pump’s motor will operate with more power the higher its horsepower is. Commercial buildings typically require grinder pumps with higher horsepower than residential homes.

Fractional-horsepower grinder pumps can typically handle a small family’s wastewater, while a large hotel produces enough wastewater to require a grinder pump with 2 horsepower or higher. Residential homes may need grinder pumps with higher horsepower if they contain multiple bathrooms.

Maximum Flow Rate

A grinder pump’s maximum flow rate determines how many gallons of water it can pump per minute. While residential homes may not produce much wastewater per hour, a commercial building may require a higher maximum flow rate to handle a significant amount of water.

Maximum Head Height

Head height is the vertical distance from the grinder pump to the highest point where wastewater exits a building to enter sewer lines. Some buildings send wastewater from the top floor to a basement and then to the sewers. If a maximum head height is 30 feet but the building’s lowest area is 40 feet below the drainpipe, it will not be able to pump wastewater far enough upwards to reach the sewer system. A sufficient head height is necessary to move wastewater from the pump to the sewer system.

Construction

Most grinder pumps are manufactured with a vertical discharge design, which is often ideal because this design features a vertical pipe. The vertical pipe allows wastewater to move upwards easily. A horizontal discharge design requires a 90-degree pipe section to move water upward.

Grinder pumps also require high-quality materials to operate efficiently and reliably. Grinder pumps with stainless steel cutters are ideal for grinding solid waste into fine pieces, and cast iron sewage grinder sump pumps are sturdy and long-lasting. Impellers should have a clog-free design, and motors should be sealed and oil-filled to reduce maintenance needs.

State and Local Codes

States, cities, and districts often have specific codes regarding sewage grinder pumps. Many states require commercial buildings to have grinder pumps, and they must adhere to certain legislation guidelines. Some states require grinder pumps to have openings and discharge pipes of a certain size and diameter. It’s important for contractors, homeowners, and business owners to understand and follow their states’ laws and codes to avoid fines.

How to Maintain a Sewage Grinder Pump

Sewage grinder pumps last longer and operate more efficiently when they are well-maintained. You can maintain your grinder pump’s life span with the following strategies:

Use Water Responsibly

Conserving water is important in any household or commercial building, but it is especially important when a grinder pump is installed. The less water a building or residence uses, the less water flows into the grinder pump’s tank. Fixing leaks and faucet drips may seem insignificant, but it can conserve a significant amount of water and reduce a grinder pump’s water intake.

Limit Garbage Disposal Use

Each time food waste enters a grinder pump, the pump activates to grind the waste. The more waste that enters the holding tank, the more frequently it will activate the pump. Increased grinder pump usage also increases the frequency it will need repairs and maintenance, so it’s essential to limit the amount of waste entering the tank. Try to dispose of as much food waste in the garbage can as possible, and limit the amount of food you send down the garbage disposal.

Flush Carefully

Certain materials and substances can clog or damage sewage grinder pumps. Avoid flushing the following items and substances down the toilet:

- Diapers

- Wipes

- Feminine hygiene products

- Condoms

- Dental floss

- Cigarette butts

- Cotton swabs

- Coffee grounds

- Paper towels

- Cat litter

- Fats, oils, grit or grease (FOGG)

- Gasoline

- Oil

- Pesticides

- Paint

- Antifreeze

- Household chemicals

- Any items that could clog the toilet

Any item that could potentially clog the toilet can also clog a grinder pump, so it’s important to only flush human waste and toilet paper. Dispose of other items in a trash can, and take hazardous chemicals to an appropriate recycling station or local hazardous materials handling station.

Minimize Excess Rainwater

Storm drains or rain drains that flow toward a grinder system can potentially fill it with rainwater. It’s important to make sure your pump is not receiving rainwater because excess water can potentially overwhelm a grinder pump or decrease its wastewater capacity. Excess water also increases a grinder pump’s pumping frequency, increasing costs for you or your business. Installing a grinder pump away from rainwater flow can reduce costs and maintenance needs.

Schedule Routine Maintenance

Routine inspections and maintenance keep grinder pumps working dependably and efficiently. Schedule annual inspections, and schedule repairs when necessary. This will increase your pump’s longevity and ensure it operates properly.

Zoeller Pump Company’s High-Quality Sewage Grinder Pumps

Zoeller Pump Company offers a selection of reliable grinder pumps to meet the needs of residential and commercial properties. Our fractional-horsepower residential grinder pumps can grind and move flushable materials for an entire residential home. Contractors can utilize these high-performing grinder pumps for challenging residential applications.

Zoeller Pump Company’s commercial options include single-direction grinder pumps, reversing grinder pumps, and grinder pumps designed with integral control. Constructed with cast-iron and stainless steel components, our 1- and 2-horsepower grinder pumps can handle wastewater produced by commercial buildings of all sizes.

Find the Nearest Distributor to Purchase High-Quality Grinder Pumps

Sewage grinder pumps are important for residential homes and commercial buildings. They grind solid waste and force wastewater upwards when a property is located below the main sewer lines. Not all buildings need grinder pumps, but buildings that cannot rely on gravity to move wastewater must have grinder pumps to prevent backups and contamination. The type of grinder pump a family or business needs depends on the size of their property and how much wastewater they produce.

Zoeller Pump Company manufactures reliable and high-quality sewage grinder pumps made in the United States using 95% U.S. content. Our residential and commercial grinder pumps work efficiently to move wastewater upwards to municipal sewer systems so families and business owners can move their wastewater effectively to protect their properties.

Locate the nearest distributor to purchase high-quality sewage grinder pumps from Zoeller Pump Company.