Pumps play an important role in homes, businesses, and institutions around the world. Without them, sinks and showers would run dry, and entire industries would be debilitated. In the U.S., for example, 82.3 million gallons of groundwater are pumped to the surface every day. Pumps that are incorrectly sized or poorly installed can impede these basic functions and cause leaks, heightened utility costs, and even increased wear on the pump and the systems around it.

This is why proper pump sizing and installation are so important. In this article, we’ll walk you through the challenges presented by incorrectly sized pumps — and how you can size and install yours the right way to avoid those problems entirely.

The Basics of Pump Sizing

Pump size is measured a bit differently than you might think. It’s less about physical size and more about the flow a pump can generate and the pressure it can manage. One of the most important things to look for is flow rate, which is typically measured using gallons per minute (gpm).

To pick the right size, you need to understand the demands of the area the pump will be supplying, especially during peak usage hours. Then, you can invest in a pump that can handle that flow rate. Oftentimes, this process involves working with a contractor or plumber trained to evaluate your needs.

The pressure your pump needs to handle correlates directly with its flow rate. The higher the flow rate, the higher the pressure produced. In technical terms, this pressure is called total dynamic head (TDH). You can calculate it by combining the friction the water will be subjected to as it moves, the heights it will have to reach relative to its starting point, and the kinetic energy generated by the motion of the water. These are called friction head, static head, and velocity head, respectively.

As with determining flow rate, working with a professional is the best way to ensure your TDH calculations are correct and you’ve selected the right pump for your needs.

Water Pump Sizing Tips

While flow rate and TDH are the most important considerations when selecting a pump, they aren’t the only ones. You should also think about:

- Differential pressure: This refers to the difference between the pressure at the inlet of the pump and the pressure at the outlet. If the differential pressure is too low, water won’t be able to reach the outlet after leaving the inlet. If it’s too high, it risks damaging the pipes and other elements of the distribution system.

- Fluid temperature, density, and viscosity: You should always consider these three factors when selecting a pump, especially if it’s for potentially dangerous fluids, like sewage and industrial chemicals. You need a pump size that can withstand and effectively pump these substances, regardless of their temperature, density, and viscosity.

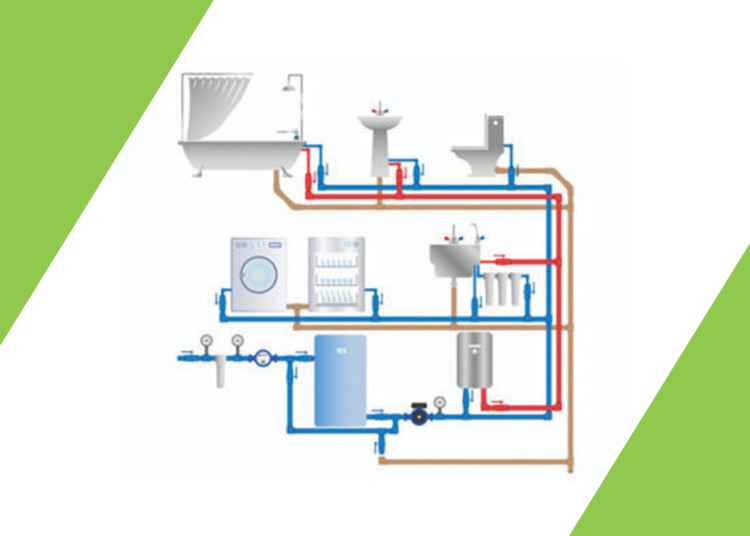

- Physical system size: Your existing distribution system and the space around it have to be able to accommodate the new pump. If they don’t, you either need to adjust the system to create space for the pump or find one that can fit within the allotted space.

Problems Caused by Incorrectly Sized Pumps

If you’re experiencing problems with your utilities, your pump may be the wrong size. If it’s too large, for example, the pump can:

- Produce excessive noise due to increased flow.

- Lower efficiency by requiring you to use bypass lines and control valves to regulate excessive flow.

- Wear down seals and bearings at an accelerated rate.

- Damage its own electrical windings by rapidly turning on and off.

Undersized pumps also pose a problem. Due to their lower capacities, they may:

- Fail to provide water quickly.

- Struggle to produce water at the proper pressure.

- Experience motor burnout, seal leaks, and other damage as a result of line blockages or unintentional valve closings.

Whether a pump is oversized or undersized, it can lead to increased utility and energy costs, decreased pump performance, and shorter lifespans. These issues can even exacerbate one another, leading to increased maintenance costs and time spent attempting to fix the pump.

Pump Installation Tips

Once you’ve found a properly sized pump, it’s time to install it. Ideally, you’ll be undertaking this task with the help of a qualified contractor, but there are still some things you should keep in mind throughout the process. For example, you should:

- Make sure the foundation can support the weight of the new pump.

- Evaluate the state of the existing piping and replace or repair sections that aren’t able to handle the pressure of the new pump.

- Support new piping so it doesn’t place excess pressure on the pump or the pipes around it.

- Regularly check the pump’s shaft alignment throughout the process.

- Test pressure, temperature, and flow once installation is complete.

These are just a handful of the necessary steps of the installation process, but they may help you prepare for the work involved. Knowing what to expect could speed up the process, especially if additional parts or repairs are required.

Common Installation Mistakes to Avoid

Installation is a complex process with many steps. It’s easy to overlook certain considerations, which can have serious consequences for your distribution system and even the people around it. As you work to install your new pump, you should avoid the following mistakes:

- Setting up the pump on an unsteady foundation and baseplate: The pump must be able to exert force against the foundation and the baseplate it’s connected to without compromising its stability. If these structures are not secure and stable, the pump may damage itself and its surroundings when active.

- Failing to check the shaft’s alignment: The pump shaft and motor must be aligned along the horizontal and vertical planes to function properly. You can check your alignment using a straight edge, dial indicators, or a laser. It’s a good idea to check and adjust the alignment regularly after installation to avoid drift.

- Connecting the pump to an inefficient distribution system: While the piping isn’t technically part of the pump, it plays an enormous role in the pump’s ability to operate efficiently and sustainably. Before installing the pump, evaluate your existing distribution system and consider ways to improve its pathing for more efficient fluid transportation. You might also find that some parts of the system need to be repaired or replaced before the new pump is installed.

- Using the pump without running a test: Tests are a vital part of the installation process. They help keep you, your pump, and the distribution system safe. You should always run a diagnostic test before you begin using the pump in earnest, as it gives you the chance to spot things like shaft misalignment, internal malfunctions, and damaged equipment before they get worse.

Size Your Pump Properly With Zoeller Pump Company

You don’t have to figure out how to size a water pump on your own. Zoeller Pump Company offers more than just the pumps we’ve honed over almost a century. We also offer a Pump Sizing Program that can help you identify and understand your exact needs, whether you’re looking for a residential pump or a commercial one. All of our pumps are made in the U.S. using 95% U.S. content, and you can find us in stores all across the country.

To learn more about pump sizing or to inquire about the pumps we offer, fill out our contact form or give us a call at 800-928-7867.